Service New Brunswick (Fredericton, NB, Canada) was selected as a finalist for ECRI Institute's 11th Health Devices Achievement Award for the simple but effective approach it used to improve completion rates for medical device inspection and preventive maintenance (IPM) procedures throughout the province.

The Health Devices Achievement Award recognizes innovative and effective initiatives undertaken by member healthcare institutions to improve patient safety, reduce costs, or otherwise facilitate better strategic management of health technology. ECRI Institute announced the winner and three other finalists for the 11th award in May 2017. For details about the other submissions that achieved recognition, see

The Health Devices Achievement Award: Recognizing Exceptional Health Technology Management.

ECRI Institute congratulates the project team members: Brett Fraser, Ron Sturge, Daniel Richard, Rejean Gauvin, and Troy Target.

The Challenge

To improve IPM completion rates for the medical devices used in the province of New Brunswick, Canada.

The Landscape

1. In 2011, the eight clinical engineering groups serving the healthcare facilities in New Brunswick were consolidated into a single group. Analyses conducted during the reorganization identified that, too often, IPM procedures were not being completed in a timely manner.

2. This problem persisted for the first few years under the new arrangement, illustrated by failures to achieve the key performance indicators (KPIs) that had been established for the facilities in this Canadian province—namely:

a) A 100% completion rate for life-critical devices (an inventory of about 1,000 devices)

b) An 80% completion rate for high-risk devices (over 10,000 devices)

Note: U.S. hospitals must comply with the Centers for Medicare & Medicaid Services (CMS) requirement to meet a 100% completion rate for all equipment. View the recording of our

January 2017 webinar for a detailed discussion of this issue.

3. Technologists would receive a list of devices that were due for inspection that month, but they were not given sufficient direction to help them prioritize the equipment on their lists. Any IPMs that were not completed during the month would spill over into the next month, compounding the problem.

The Process

1. The tide began to turn in 2013, when the organization embraced the "critical percentage" concept to help technologists better prioritize their worklists.

a) The critical percentage is a single value that communicates the urgency for performing any particular IPM at any given time. It is used instead of, and provides more information than, a due date.

b) While not the first organization to use the critical percentage concept, Service New Brunswick demonstrated the benefits that can be realized when an organization commits to this approach.

2. The critical percentage for each piece of equipment is determined by dividing the number of days since its last inspection by the recommended frequency of inspection (in days). That figure is then multiplied by 100 to obtain a percentage:

| Days Since Last IPM | |

| × 100 = Critical Percentage |

| IPM Frequency (in Days) | |

3. Whereas the due date communicates only when an inspection is due for a piece of equipment, the critical percentage expresses the due date in relation to the recommended IPM frequency for that piece of equipment. In this way, it helps technologists prioritize their work by identifying the most urgent IPMs to complete at any given time.

4. Consider the following example:

|

Device |

IPM Frequency |

Days Since Last Inspection |

Days Overdue |

Critical Percentage |

|

A | 1 year (365 days) | 408 | 43 | 112% |

|

B | 6 months (180 days) | 197 | 17 | 109% |

|

C | 3 months (90 days) | 104 | 14 | 116% |

a) In this example, three devices are overdue for inspection:

(1) Device A, which has an inspection interval of once a year, was last inspected 408 days ago. Its critical percentage is (408 ÷ 365) × 100 = 112%.

(2) Device B, which has an inspection interval of once every six months, was last inspected 197 days ago. Its critical percentage is (197 ÷ 180) × 100 = 109%.

(3) Device C, which has an inspection interval of once every three months, was last inspected 104 days ago. Its critical percentage is (104 ÷ 90) × 100 = 116%.

b) Judging by just the due dates, device C would appear to be the lowest priority since it is only 14 days past its due date, compared with 43 and 17 days overdue for the other devices. However, the critical percentage values show that device C should in fact be given the highest priority, resulting from its need for more frequent inspections.

5. Service New Brunswick incorporated the critical percentage into its in-house-developed computerized maintenance management system (CMMS) in early 2014. To help staff shift away from the due-date mindset, the critical percentage value was displayed instead of the due date in all equipment records, on every work order, and within the dashboard that is used to drive the IPM program.

6. Using the dashboard, technologists are able to filter and sort the equipment list—for example, by critical percentage—to identify equipment in need of inspection and to generate a work order for that IPM.

The Results

1. Productivity enhancements—Service New Brunswick reports that its implementation of the critical percentage concept has improved productivity, resulting from benefits such as the following:

a) The availability of a single number that shows the IPMs that warrant priority status on any given day. This information removes the guesswork about how technologists should prioritize their work.

b) The ability to sort equipment lists by critical percentage. This allows technologists to identify the devices that are coming due for inspection, and those that can wait.

c) The presence of the critical percentage value in equipment records and on work orders. This allows technologists to see the IPM status for a piece of equipment whenever they are working on that equipment.

(1) If the critical percentage is approaching 100%, the technologist can take that opportunity to also perform the IPM.

(2) If the critical percentage is over 100%, a pop-up window notifies the technologist that the IPM is required.

2. Improved reporting capabilities—Using a single number simplifies generating reports that allow technologists, managers, and administrators to track progress toward meeting the organization's IPM goals for each facility in the system.

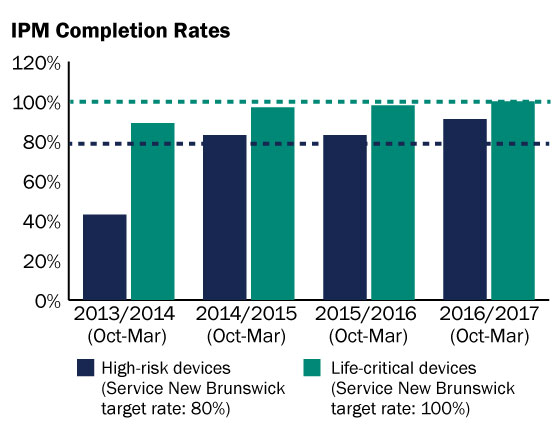

3. Achieving KPIs—The graph below shows the extent to which IPM completion rates have improved since the critical percentage concept was introduced. (Totals encompassing all eight facilities are shown.)

a) Data from the last half of the 2013/2014 fiscal year show that the organization was not meeting its target completion rates (80% for high-risk devices, 100% for life-critical devices).

b) Data from subsequent years show marked improvement and consistent performance.

Key Takeaways

1. Fully integrating the critical percentage concept into the CMMS and the organization's workflow has brought structure to the process. It allows technologists to make more informed decisions about how to approach their IPM tasks, and it allows managers to better track progress toward meeting the organization's goals.

2. Shifting away from the due-date mindset was a real culture change. However, the value of the critical percentage approach quickly became apparent once technologists began using it. The term is now an integral part of the team's vocabulary.

3. At the time the critical percentage concept was introduced, the organization was still trying to get individuals at different facilities to work as one unit. This concept was one change that has helped Service New Brunswick improve its IPM completion rates and achieve consistent results across the eight facilities it manages.